Aeroquip 601 / AE701 Hose

| Description | Tubing Size | Hose ID | Min PSI | Wgt/Ft | PN | Price | Buy |

|---|---|---|---|---|---|---|---|

| Aeroquip 601/AE701 Hose | .398 | .141 | 1500 | .093 | 601-3 | $33.55 | |

| Aeroquip 601/AE701 Hose | .462 | .204 | 1500 | .114 | 601-4 | $34.65 | |

| Aeroquip 601/AE701 Hose | .508 | .266 | 1500 | .145 | 601-5 | $36.85 | |

| Aeroquip 601/AE701 Hose | .571 | .329 | 1500 | .155 | 601-6 | $37.35 | |

| Aeroquip 601/AE701 Hose | .673 | .415 | 1250 | .170 | 601-8 | $42.68 | |

| Aeroquip 601/AE701 Hose | .820 | .539 | 1250 | .207 | 601-10 | $50.33 | |

| Aeroquip 601/AE701 Hose | .961 | .665 | 1250 | .285 | 601-12 | $51.54 | |

| Aeroquip 601/AE701 Hose | 1.187 | .844 | 1000 | .380 | 601-16 | $72.33 | |

| Aeroquip 601/AE701 Hose | 1.468 | 1.094 | 800 | .490 | 601-20 | $85.53 | |

| Aeroquip 601/AE701 Hose | 1.734 | 1.344 | 400 | .675 | 601-24 | $103.13 | |

| Aeroquip 601/AE701 Hose | 2.140 | 1.750 | 350 | .903 | 601-32 | $126.23 |

Overview

|

An inner tube of seamless, specially formulated synthetic rubber reinforced with a stainless steel partial inner braid and full-coverage stainless steel outer braid. Operating temperature -65 to 300F. Aeroquip 601 hose is widely used for aircraft fuel and oil lines where flexibility and light weight are prime considerations. Because of its lighter weight and lower operating pressure than type 303 hose, it is not recommended for hydraulic lines. Use with Aeroquip 816 hose fittings. Aeroquip 601/AE701 is a direct replacement for old 601 hose. AE701 hose has no shelf life and is the upgraded version of 601 hose.

Construction: Synthetic rubber inner tube with two layers of stainless steel wire braid reinforcement. Basic Specification: MIL-H-83797, TSO C53a, Type A. Application: Fuel, engine oil, and coolants. Sold by the foot. |

Features

- Flexibility

- Light weight

- Non-age sensitive

- Fluid temperatures: -65°F (-54°C) to +300°F (+149°C)

- TSO C53a, Type A and Type C approvals (with fire sleeve)

- Mil-Spec Approvals: MIL-H-83796/1 through MIL-H-83796/9 Assemblies & MIL-H-83797 Hose, MIL-F-83798 Fittings

- Field attachable fittings

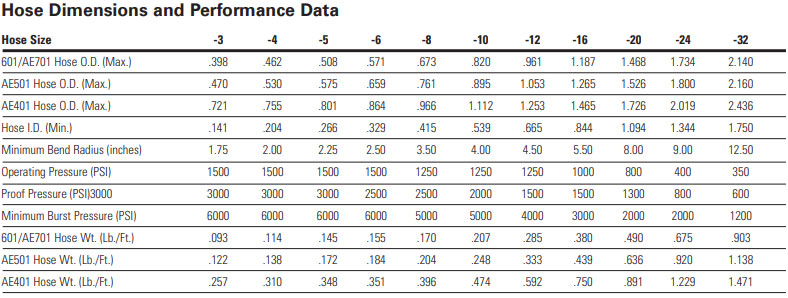

Specifications

Reviews

Good product

Eaton Aeroquip 601-4 / AE701 Hose

Very good product

Eaton Aeroquip 601-8/AE701 Hose

Eaton Aeroquip 601-8/AE701 Hose

Eaton Aeroquip 601-4 / AE701 Hose

Eaton Aeroquip 601-10 / AE701 Hose

Eaton Aeroquip 601-6/AE701 Hose

Q&A

Please note, Aircraft Spruce Australia's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Australia assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

You should avoid using barbed fittings, especially on fuel lines. Barbed fittings tend to contaminate the hose, this can be a bad situation on your Rotax motor since there is not a filter between the pump and carburetors. As usual you should check your float bowls for contamination for the first 10-15 hours after replacing any fuel hoses. As far as if you can use worm drive clamps on Aeroquip 601 hose, no you cannot. Aeroquip 601 hose is designed to be used with 816 fittings. The best option for your Rotax motor is to use Super-Flex hose, clamped with Band-It clamps and covered with firesleeve.

The Aeroquip 601-3 is the closest size to the Stratoflex 156-3.

Yes, this hose and fitting combination can be used in certified aircraft.

This would be use the 816-3 fitting.

Aircraft Spruce Australia

Aircraft Spruce Australia