THE AVIATION SUPERSTORE FOR ALL YOUR AIRCRAFT & PILOT NEEDS | +61 (1800) 953522

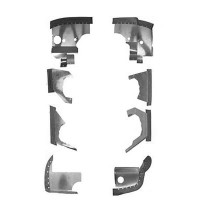

Elevator Trim Skin Cessna 170 / 190 / 195

From $276.05 to $577.50

Prices below incude GST

Overview

|

The outboard tip of the elevator trim skins for the Cessna 170, 190 and 195 has always been an area prone to cracking. This is because the original skins had a formed corrugation at the tip that had to be "unformed" or flattened either at the factory or in the field before it could be securely riveted in place.

The process of forming that corrugation and then flattening it again work hardens the material, making it brittle and prone to cracking around the rivet. The precision hydraulic forming process allows the manufacturer to skip the final corrugation in the skin, leaving the problem tip unformed and ready to rivet. This is in contrast to Cessna's rotary forming process, which does not allow the option to skip a corrugation. |

Features

- More precise corrugation spacing and shape

- No pre-drilled holes to misalign

- Precisely formed and CNC cut to shape to match OEM skins

- Plastic coated on both sides for better protection during handling (remove before installation)

- Direct replacement - No STC required

Documents

Q&A

Please note, Aircraft Spruce Australia's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Australia assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Australia

Aircraft Spruce Australia