Joe Brown's Sportsman 2+2 & 2 Weeks To Taxi By David Gustafson

|

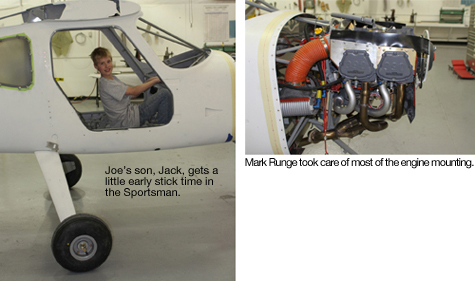

Joe Brown liked that idea and signed up in November 2010. He showed up for work at 6:30 a.m. on May 5, 2011 and was pleased to see that his Build Leader and “team” were already there. After coffee, doughnuts and a tour of the workshop, Joe plunged in. The night before he had studied the manual for the work to be completed on Day One and progress was swift. Every part needed for the day’s work was laid out on tables and shelves. Every tool was color coded and contained in large tool chests. An enormous checklist was hanging on the wall that guided him step by step through the process. Joe had some help from his eleven-year-old son, Jack, and an A&P mechanic/friend named Mark Runge. They worked from 7:30 to noon, took 30 minutes for lunch before going back at it until 5:00. That was quitting time, but Joe often found himself finishing up, cleaning up and debriefing with his Build Leader until 6:00. He’d go off for dinner, then he’d hit the books for the next day’s activity until it was time for sleep. The pace was intense and the progress each day was amazing. As members of the team directed him from one task to another, they would explain the function of each part he was fabricating, assembling or installing, taking time to articulate what it was for and how it would affect flight.

Mark is exceptionally skilled and focused on firewall forward, drawing Joe in

Other than selecting engine size (Lycoming 390), panel instruments, upholstery fabric, and the paint scheme/color, there’s no room for customizing a Sportsman 2 + 2. The builder must adhere to the plans and the parts provided for the project. In that sense, every 2 + 2 is as identical as a gaggle of factor- builts. Joe exercised the option of being able to configure the aircraft as a tricycle gear and taildragger. He first flew his trike on May 20th, a flight that he describes as “among the highlights of my life”. He went on to say: “I have a much more refined appreciation for the guys who have designed, built and done flight testing since 1903. In my case, I just had to prove it was built right.” It was. Since completion he’s run up over 100 hours on the Hobbs and reports that the aircraft exceeded his expectations in many ways. His only reservation: “I might debate building a VFR version just to get the airplane out the door quicker.”

Joe Brown is President of Hartzell Propeller. His father, Joe, Sr., a former Naval Aviator, bought Hartzell in 1987, so Joe grew up in an aviation family and got his Private right after graduating from college. He also began working for his father right after school and 20 years later, he and his brother, Jim, bought out the company.

“Why homebuilding? Several of my co-workers built airplanes. I admired them for their effort, skill and passion. I wanted to give my kids their own, personal way to engage in an airplane we could fly together. It could be “our” airplane…an alternate version of what my dad and mom did for me.” For more information about the Sportsman 2 + 2 visit www.GlasairAviation.com.

|

Aircraft Spruce Australia

Aircraft Spruce Australia

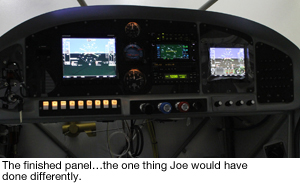

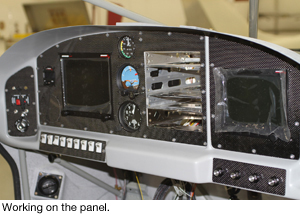

when there was something requiring connection or installation. Otherwise Mark led the charge. He also was lead on the panel and its maze of wiring. Joe had opted to go full IFR with the panel, installing Advanced Flight Systems EFIS along with Garmin Nav/Coms, weather radar and TCAS. It’s a full glass cockpit. Jack took on the tail structure, installing and rigging the rudder and elevator.

when there was something requiring connection or installation. Otherwise Mark led the charge. He also was lead on the panel and its maze of wiring. Joe had opted to go full IFR with the panel, installing Advanced Flight Systems EFIS along with Garmin Nav/Coms, weather radar and TCAS. It’s a full glass cockpit. Jack took on the tail structure, installing and rigging the rudder and elevator.