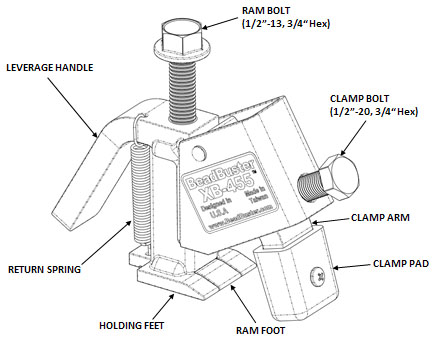

Beadbuster XB-455 ™

MFR Model# XB-455

Overview

| The BeadBuster XB-455 was designed to work on even the most difficult tires, which means it can make quick work of all general aviation light aircraft tires. An innovative new design requires no adjustment for different sized rims and no floor space required to set up. Precise, powerful control will ensure professional results without damaging rims. Change your own tires whenever, and wherever you want.

Weight 3 lbs Dimensions 6 x 6 x 1.75 in |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

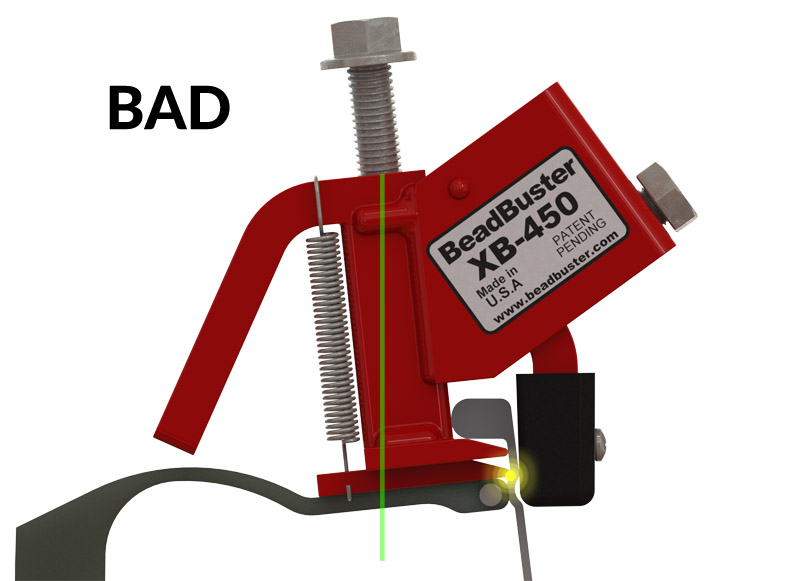

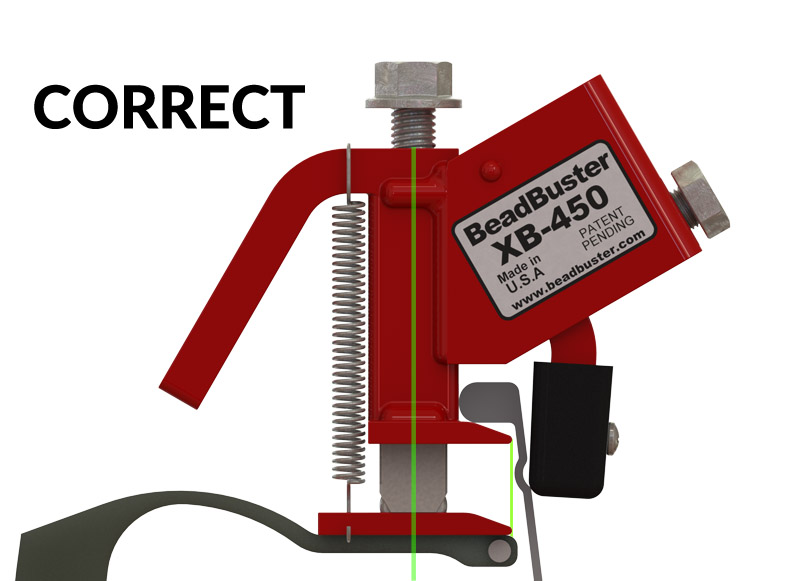

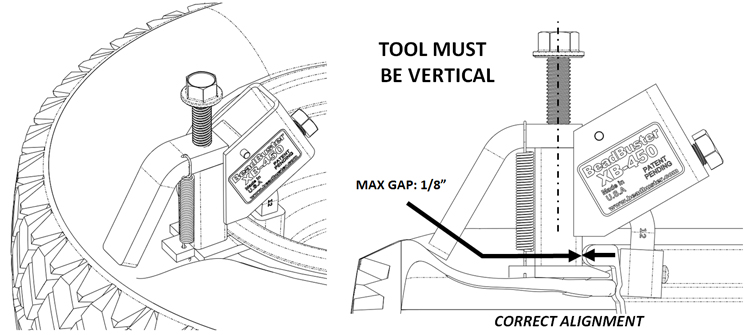

| 6. Use a 3/4" socket or wrench to run down the Ram Bolt until the tire bead has been pushed past the bead retainer on the rim. Again, an impact wrench can be used, but be cautious with a 1/2" impact so that you don’t over-torque the bolt, which could strip the threads.

Depending on the age of the tire and condition of the rim, the bead may partially return to the seated position when the Ram Foot is retracted. If this happens, insert a small block of wood or plastic between the tire and rim to prevent it from re-seating. ***CAUTION*** Do not allow fingers or body parts to get pinched between the bead and rim! |

7. The bead retainer on the rim will be visible after pushing the tire bead past it. It is recommended to visually inspect the gap during operation to ensure the Ram Foot does not catch on it. There is a tendency to want eagerly to push the bead down all the way in one spot, however the BeadBuster only has 1.438" of travel. Observe when the Ram Bolt has bottomed out on the top of the tool body, and make sure not to tighten beyond that point, or you can strip the threads with a powerful wrench. | ||||||||||||||||||||||||

|

|||||||||||||||||||||||||

Features

- Designed in USA, made with care in Taiwan

- Durable Steel Construction (AISI 1020 Cold Rolled)

- Extra-strong Ram Foot is made from Hardened & Tempered 4130 Chrome-Moly Steel, with a Proof Load of >3,000 lbs

- MIG Welded

- Grd-5 & Grd-8 Hardware

- Polyester Powder Coat Finish

- Padded Clamp Arm (Will not scratch or dent rims)

Specifications

- Weight: 2.93 lbs

- Size: 6″ x 6″ x 1-3/4″

- Max Rim Lip Width (clamp opening): 1.70″

- Max Rim Lip Thickness: 0.63″

- Rim Diameter: Any

- Rim Width: Any

- Rim Material: Any

- Max Ram Extension (throw): 1.438″

Important Notes

- The BeadBuster XB-455 was designed for use on all common Diameters of GA Light Aircraft Rims. It’s effectiveness has been proven on 5.00 x 5 rims.

- The clamp pad screw may need to be removed to ensure clearance with the center hub if you are using early revision copies of the XB-455.

- A 3/4″ wrench is required to drive the clamp and ram bolts. Hand wrenches will work, power tools are recommended. You can use an impact wrench, but use caution with a 1/2″ impact to not over-torque the bolts.

Documents

- Use Instructions (PDF)

Videos

Reviews

Used it on a 6.00–6 tire today, works flawlessly. Recommended for anybody! Takes up much less space than a typical bead breaker, even if it takes slightly more time.

Beadbuster Xb-455

Ill admit I was skeptical when I first looked at this tool. But it works, and it works well. Piece of cake to break the tire bead.

Beadbuster Xb-455

Tried it the first time, I am very impressed with the simplicity of its use and the quality of its construction

Beadbuster Xb-455

Great tool. Works as advertised, a “must” for every hangar.

Beadbuster Xb-455

Used it for the first time today. All I can say is WOW!!! This thing is quick and stupid easy to use. Its super compact and easy to throw in a toolbag for a job on the road. Ill be interested to see if I ever need to use my full-size shop bead breaker again. Well done! Excellent product!

Excellent tool, very sturdy. I used it to breakdown a number of 6.00x6 and 5.00x5 Cessna tires on its first day. Very quick and its portability is very handy. Easy to use on the bench top. Absolutely no damage to the rim. I have owned the Bogert unit for 12 years and find it tedious to use and very bulky. The tire constantly moves when applying force and you must shove your foot against the tire to hold it in place. I have broken down literally 100s of tires on it and I feel every time is like the first time, the results are very unpredictable. There is no difference in the time it takes to use this tool vs the Bogert, both take about 2 minutes or so per tire. I like that it is bright yellow, make it easy to find in a busy shop. The Bogert is so bulky that it is always getting stashed somewhere and you cat find it!!!

Great tool, work perfectly!

Received the bead buster in record time. Very happy with the service. The tool works as advertised. I had two truck tires that were constant leakers on my 2008 GMC Sierra 1500. Broke the bead and cleaned the rims. The tool did the job. Quite surprised how it worked so well. I have numerous ATVs tires to do as well. Looking forward to see how those work. I also bought this tool to change out tpms sensors. Looks like it will do that job too.. Great little tool..a bit pricey but does the job well. It’s also very portable which was a bonus for me. I do recommend this tool..

It works, used to break the bead on 18 inch GMC Sierra tires.

Awesome tool, works awesome incredibly easy and quick

Q&A

Please note, Aircraft Spruce Australia's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Australia assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Yes, the XB-455 will work on 5.00 x 5 tires. We have added the installation manual to the 'Documents' tab of the web page. Please review it there. We have also added a youtube video demonstrating use of the XB-450, which is used similarly to the XB-455.

Aircraft Spruce Australia

Aircraft Spruce Australia