THE AVIATION SUPERSTORE FOR ALL YOUR AIRCRAFT & PILOT NEEDS | +61 (1800) 953522

EAM T4 Man Single Tube Type II Raft Far 121

$5604.50/Each

Price Includes GST

Part# 13-16560

MFR Model# R0101A601

MFR Model# R0101A601

Overview

|

Each product is manufactured with the highest quality craftsmanship and are proudly FAA-TSO approved. In addition, EAM is proud to offer customizable raft packaging to meet any client’s specifications. When deployed and in the water, the raft may be boarded on either side. Survival items are contained in a kit tied to the raft. Select raft models include a raft canopy, located inside the accessories case, which features two (2) roll-up doors and a rain water collector in the top of the roof panel. The VIP and SAM Series life rafts have auto self-erecting canopies, which have two (2) doors which can be sealed closed with Velcro. Also, the VIP and SAM series canopies are affixed to the life raft with Velcro so if needed the canopy can be removed and reinstalled. USA: FAA TSO-C70a, Type II Germany: LBA No. 40.320/12 Japan: JCAB No. 535

Overload Capacity: 6 Carrying Case: Soft Valise |

Features

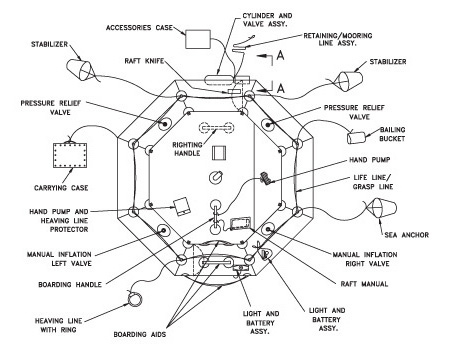

- Flotation tube, compartmentalized into two chambers by vertical bulkheads, fabric deck attached to tube structure

- Combination life line assists in boarding

- Lanyard-activated rafts

- Manually-operated carbon dioxide (CO2) inflation system

- Manually-operated hand pump, secured to the boarding station

- Full inflation/topping off of the flotation chambers as required

- Each of the two compartmentalized chambers is maintained to equal pressure by individual pressure relief valves

- Raft instruction manual tied to the boarding handle

- Canopy/survival kit stowed in accessory case attached by line to raft life line

- Door opening with roll up door cover and rainwater collector

- Sides may be raised or lowered

- Non-Transport Series rafts have Federal Aviation Regulation (FAR) Part 135 survival equipment, radar reflector is an integral part of the canopy

- Rafts with survival equipment under FAR Part 121 rules do not require, and thus do not have a radar reflector unless ordered as special option

Specifications

| Capacity | Rated: 4 Persons Overload: 6 Persons |

| Approval | USA: FAA TSO-C70a, Type II Germany: LBA No. 40.320/7 Japan: JCAB No. 535 |

| Color | Raft: Yellow Carrying case: Yellow Canopy: Orange |

| Diameter Raft Tube | 12.4" (31.5 cm) |

| Inflated Volume: @ 1.50 psig | Total: 14.12 ft.3 (0.4 m3) |

| Tube Volume Per Person: @ rated capacity | Total: 4.07 ft.3 (0.12 m3) |

| Total Tube Buoyancy | 881 lbs. (399.62 kg) |

| Buoyancy Per Person: @ rated capacity | 20 lbs. (99.8 kg) |

| Total Deck Area | 14.7 ft.2 (1.37 m2) |

| Deck Area Per Person: @ rated capacity | 3.7 ft.2 (0.34 m2) |

| Tube Operating Pressure | 2.0 psig (0.138 bar) |

| Pressure Relief Valves | Open: 3.0 psig (0.207 bar) Close: 2.0 psig (0.137 bar) |

| Tube Burst Pressure | Over +10 psig (+0.69 bar) |

| Inflation System | Cylinder Size: 82 in.3 (1.34 cm3) Cylinder Type: DOT 3AA-2100 Charge Weights: CO2 : 2.01 0.03 lbs. (.911 0.01 kg) |

| Environmental Limits | |

| Temperature | Functional Range: -40 to 130 °F (-40.0 to 54.4 °C) Storage Range: -65 to 160 °F (-54 to 71 °C) |

| Humidity | Up to 95% relative humidity |

| Altitude | -2000 to 45,000 ft. above sea level |

| Service Life | Indefinite if raft continues to pass periodic maintenance inspection |

| Frequency Of Inspection | Every 12 months, recommended. |

Reference Chart

Q&A

Please note, Aircraft Spruce Australia's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Australia assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Australia

Aircraft Spruce Australia