U Type NAS395 (A1787-10Z-1)

| Tinnerman No. | Screw Size | Part Number |

|---|---|---|

| A1787-10Z-1D | #10 | A1787-10Z-1D |

Overview

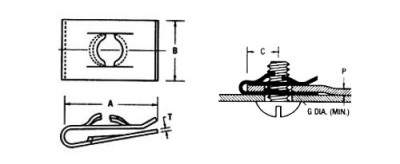

| Snaps over edge of panels or into center hole locations. Holds itself in place for blind assembly. "Floats" free for easy hole alignment. |

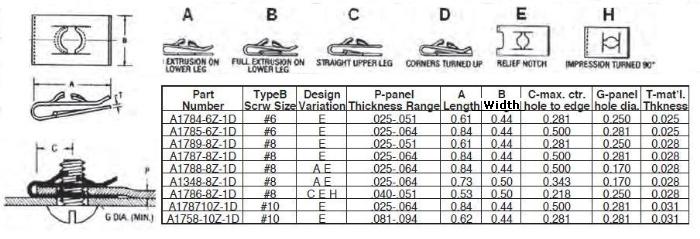

Specification Chart

Instructions

HOW TO APPLY SPEED NUT FASTENERS | |||

| FLAT TYPE | "U" TYPE | ||

| Fastener is positioned over screw clearance hole with screw-engaging prongs pointing up or outward. Screw is started into nut by hand from the underside. |  | Push into position with thumb until extrusion on lower leg snaps into screw hole. The fastener "floats" in screw-receiving position to correct for normal misalignment in panel mounting holes. |

|

| Screw can be power-driven into locked position (when base arch of fastener is flat) or a hand screw driver can be used. No wrench is required, finger pressure will prevent it from turning. |

| Place second panel in position and drive screw. Access to opposite side is unnecessary. Flush mounting can be made by embossing either panel. |

Reviews

Product was delivered exactly as ordered.

U Type NAS395 (A1787-10Z-1) (Pack Of 25)

Thanks

U Type NAS395 (A1787-10Z-1)

good product

U Type NAS395 (A1787-10Z-1)

U Type NAS395 (A1787-10Z-1)

U Type NAS395 (A1787-10Z-1)

U Type NAS395 (A1787-10Z-1) (Pack Of 25)

U Type NAS395 (A1787-10Z-1)

I was more than happy with the way my order went. I was informed in detail about every step. Despite a very small and cheap order, I got things extremely quickly. Keep it up!

Looks great!

Good quality! Easy to use and good, tight fit to hold them in place!

Q&A

Please note, Aircraft Spruce Australia's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Australia assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

We have added a new specification chart both above the product listing and in the "Specification Chart" tab. It references each of the dimensions for clearly. G is a minimum diameter.

Tinnerman NAS395 nuts are used with sheet metal screws. Machine screws would require a Tinnerman LHA or Monadnack clip nuts. The screw size for machine screws will indicate the size, and thread count, 6-32, 8-32, etc.. Sheet metal screws are indicated by size and type, #6 type A, or #6 type B, etc..

SAE 1065-1070 steel.

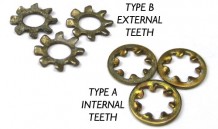

Yes, type A and B will work with these.

Aircraft Spruce Australia

Aircraft Spruce Australia