West System Epoxy Components

| Component | Description | Part No. | Price | Buy |

|---|---|---|---|---|

| Resin | 105-QT (32 oz.) | 01-00353 | $56.62 | |

| Resin | 105-1G (126 oz.) | 01-00354 | $125.43 | |

| Resin | 105-5G (4.35 gal.) | 01-00355 | $437.80 | |

| Fast Hardener | 205-1/2PT (7 oz.) | 01-00356 | $38.14 | |

| Fast Hardener | 205-QT (27 oz.) | 01-00357 | $81.35 | |

| Fast Hardener | 205-1G (121 oz.) | 01-00358 | $240.90 | |

| Slow Hardener | 206-1/2PT (7 oz.) | 01-00359 | $33.97 | |

| Slow Hardener | 206-QT (27 oz.) | 01-00360 | $72.82 | |

| Slow Hardener | 206-1G (121 oz.) | 01-00361 | $208.73 | |

| Extra Slow Hardener | 209-1/2PT (7 oz.) | 01-00362 | $56.47 | |

| Extra Slow Hardener | 209-QT (27 oz.) | 01-00364 | $119.15 | |

| Extra Slow Hardener | 209-1G (121 oz.) | 01-00363 | $350.90 | |

| Special Clear Hardener | 207-1/2PT (7 oz.) | 207-SA | $62.69 | |

| Special Clear Hardener | 207-QT (27 oz.) | 207-SB | $125.86 | |

| Special Clear Hardener | 207-1G (121 oz.) | 207-SC | $403.70 |

Overview

|

WEST SYSTEM brand resins and hardeners, form a two-part epoxy system developed by Gougeon Brothers specifically for wood and composite construction. WEST SYSTEM epoxy is recommended by Rutan Aircraft Factory for certain homebuilt aircraft applications, particularly where a moisture resistant epoxy is desired. 105 Resin is the base material on which all of the WEST SYSTEM epoxy systems are built. The resin is a clear, light amber, low-viscosity liquid. It is designed specifically to wet out wood fiber. With roller applications, it possesses excellent thin film characteristics in flowing out and is self-leveling without fish-eyeing. Its relatively high flash point makes it safer to work with than polyesters. It can be cured in a wide temperature range, then sanded and shaped. It cures quite clear so that the natural finish shines through.

205 Fast Hardener, when mixed with the 105 Resin in a ratio of 5 parts Resin to 1 part Hardener, yields a high-strength, rigid solid with excellent cohesive properties and provides an excellent moisture vapor barrier. The 105 Resin/205 Fast Hardener has a pot life of 10-15 minutes at 70°F. It is also recommended in coating applications where natural finishing is desired. Partial cure time at 70°F is 5-7 hours. 206 Slow Hardener is a low-viscosity mixture of polyamines. The 105 Resin/206 Slow Hardener has a pot life of 30-40 minutes at 70°F. It is normally used when extended time is needed for large coating and bonding applications. It is especially well suited to working in warmer climates. Partial cure time is 9 hours at 70°F. Order by size and hardener. Pump sold separately. |

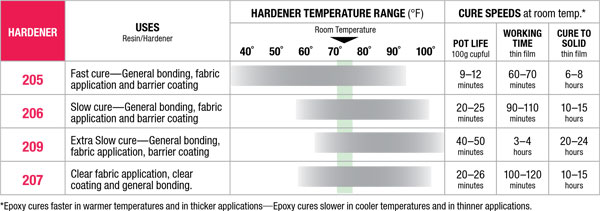

Selection Guide

Documents

- West System User Manual (PDF)

- 105-205 TDS (PDF)

- 105-206 TDS (PDF)

- 105-207 TDS (PDF)

- 105-209 TDS (PDF)

- 105 SDS (PDF)

- 205 SDS (PDF)

- 206 SDS (PDF)

- 207 SDS (PDF)

- 209 SDS (PDF)

Videos

Reviews

West System Epoxy 206 Slow Harener 1/2

West System Epoxy 105 Resin Quart

West System Epoxy 206 Slow Hardener Quart

Fast shipment

West System Epoxy 205 Fast Hardener Quart

West System Epoxy 105 Resin Quart

West System Epoxy 105 Resin 1G

It is indeed fast. The trick is to plan ahead and don’t be shy - get it out of the pot and spread out to limit runaway exothermic reaction

West System Fast Hadener 205 1G

I’m using this for marine use. Pricey stuff, but for boats or planes, you don’t want to take chances. West system has been around forever and is a top product.

West System 105 Resin 5G

Have used West System Epoxy for a number of applications and very easy to work with and great results.

West System Epoxy 206 Slow Harener 1/2

West System Epoxy 105 Resin Quart

Q&A

Please note, Aircraft Spruce Australia's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Australia assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

The West Systems epoxy does not have a haz mat charge if shipped domestic USA ground service.

In general, epoxies are not recommended for use with fiberglass mat material. Uni or Bi directional woven cloth only.

The 205 hardener will have a pot life at 72F/22C: 9 to 12 minutes. The 206 hardener will have a pot life at 72F/22C 20 to 25 minutes.

Shelf life foe the West Systems 105 system is as follows:

Store at room temperature. Keep containers closed to prevent contamination. With proper storage, resin and hardeners should remain usable for many years. After a long storage, verify the metering accuracy of the pumps. Mix a small test batch to assure proper curing.

Over time, 105 Resin will thicken slightly and will therefore require extra care when mixing. Repeated freeze/thaw cycles during storage may cause crystallization of 105 Resin. Warm the resin to 125°F and stir to dissolve crystals.

Hardeners may darken with age, but physical properties are not affected by color. If clear finishing, be aware of possible color shift if very old and new hardeners are used on the same project.

If you mix the hardener and resin you have a working time of 10-15 minutes for the fast and 30-40 minutes for the slow. The resin and hardener have a shelf life of 3 years.

Aircraft Spruce Australia

Aircraft Spruce Australia