284-50 Carbon Fiber Fabric

MFR Model# 284-50

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

| Style # | Style | Weight Oz/Sq.Yd | Width / In | Thickness | Weave & Fill | PN |

|---|---|---|---|---|---|---|

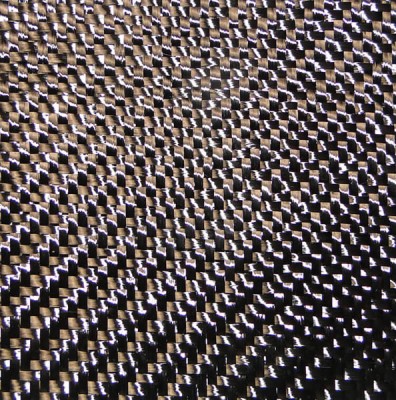

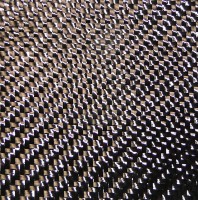

| 284 | Twill 2/2 Weave 3K | 5.7 | 50 | .007 | 12 x 12 | 01-00602 |

Overview

|

Woven graphite is an excellent alternative to fiberglass and Kevlar - only mils thick with great strength. In addition to its great strength, graphite fabric also has very low density and is very stiff. Although it is quite costly, the material saving is appreciable since only one course of graphite is required for 3 or 4 of fiberglass. It cuts considerably easier than Kevlar. The excellent qualities of the graphite fabric itself give it an immediate waiting market in the aircraft building field. Carbon fibers are produced in a continuous operation, during which the polyacrylonitrile (PAN) precursor undergoes a series of precisely controlled processes. By exposing the precursor to extremely high temperatures, chemical changes occur which create high strength and stiffness to weight ratios through oxidation, carbonization and graphitization. Subjecting the precursor to successive heat treatment and sizing stages makes for easier handling and improved bonding, resulting in a material that is stronger than steel, lighter than aluminum and as stiff as titanium. Carbon fiber reinforcements, when properly engineered into the appropriate matrix, can achieve one of the strongest and most rigid composite structures available with significant weight savings when compared to metals and other materials. In addition to the high strength-to-weight ratio, carbon fiber reinforcements are thermally and electrically conductive, have very low CTE and excellent fatigue resistance. |

Reviews

lays up well, got a good end product my first try with carbon fiber, had only worked with glass before.

284-50 Carbon Fiber Fabric

I used this on empennage fairing, conformed excellent around multiple curves! Definitely 50 wide is ENOUGH, stuff is very delicate to work with. Confused to chose between this Bi-direct. vs Twill, VERY happy I chose Bi-dir. This will yield that traditional look of carbon fiber that we typically see.

284-50 Carbon Fiber Fabric

Very good and sturdy weave. Best Ive used so far.

284-50 Carbon Fiber Fabric

Laid in the mold perfect.

Quick and easy access. solid tight weave well protected during shipping.

Works great, wish it wasnt so expensive.

This fabric is the best weave for complex curves. It works well wets well, Excellent!

The strength is awesome and lays well.

Always great service...always my source Rapid shipping

Good stuff easy to work with

Q&A

Please note, Aircraft Spruce Australia's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Australia assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

We can only recommend to use the materials called out in the aircraft plans. Carbon fiber is a much stiffer material than fiberglass and we do not have any tests to compare how the aircraft would perform using carbon fiber.

Yes, we can roll it in the 36" width, but we do suggest making a note of it in the special instructions when ordering.

The carbon tow can be pulled apart from the woven cloth if desired. Twill 2/2 is in reference to the type of weave of the fabric. We stock carbon fiber woven in Twill 2x2 and plain weave.

If the weight and the weave are the same as the fiberglass cloth then yes, the procedure will be the same.

This material is priced and sold per linear yard at the width shown in the ordering chart.

The general difference is that the plain weave is woven a little tighter than the twill, so plain weave generally deoesn't lay-up around contours as well as the twill. As far as cosmetics, the twill is commonly used.

Per Supplier: Yes Carbon is always better than glass.

Per your description it sounds you are looking for a filler in which is a sandable epoxy. You can use the PTM&W light weight filler (part # 02-30006) or the Superfil (part # 09-28250) for this application.

Yes. Vinyl Ester resin can be used with carbon fiber cloth.

You would typically want to use an epoxy resin when working with carbon fiber.

Aircraft Spruce Australia

Aircraft Spruce Australia